Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Books & Movies

- Cockpit Confessions

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

Tuning A Sailboat Rig

Advertisement

If your sailboat seems slower, follow our how-to on tuning your rig for optimal performance.

Photo: Bigstock

Spring is a time of prepping your boat for the coming season. While powerboaters fine-tune their engines, sailors should consider fine-tuning their rigs. Doing it yourself may seem intimidating, but it shouldn't be. Anyone reasonably handy can do it in a few hours. The reward is easier and faster sailing throughout the coming season.

Let's start with the basics for new sailors. With a few exceptions, a sailboat mast is held up by a series of stainless-steel wires. But those wires also perform several other equally important functions. When a sailboat is at rest and there is no wind blowing, the stress on these wires is very light with almost all the load downward toward the keel. However, when the boat is sailing and heeled over in a fresh breeze, more stress is placed on the wires and they have to work harder to hold the mast upright and stop it from bending.

The wires that prevent the mast from moving from side to side are called shrouds, and the ones that prevent fore and aft movement are called stays. The larger and taller the mast, the greater the load, and the number of shrouds and stays required. On a typical cruiser, say up to about 35 feet, there will generally be one forestay, one backstay, and two shrouds on each side.

To get the best performance from your boat and sails, the rigging needs to be set up correctly — often called "tuning the rig." The rig should be tuned with the boat in the water on a day with little to no wind. You'll also want to be away from wakes and other boats that can rock your boat. To start, the turnbuckles for the stays and shrouds should be hand-tight only. This is sufficient to hold up the rig but places no strain on anything — yet. Lay on your back on the boat's foredeck and sight up the front of the mast. It should be perfectly straight with no bends or kinks. Next, tighten the lower shrouds — these are the ones that do not go all the way to the top of the mast and often attach to the mast at the base of the crosstrees (the two horizontal spars at the upper ends of the topmasts).

You'll need a large screwdriver to rotate the turnbuckle, and a wrench to hold the shroud fitting and prevent it turning as you tighten. Give a couple of complete turns on either side. Have a helper release the main halyard and keep a little tension while you pull down the end that normally attaches to the mainsail until it just touches the top of the toerail adjacent to the chain plate. Have your helper cleat off the halyard, then swing the halyard over the boom and check the measurement on the other side. They should be the same. If not, adjust the turnbuckles until they the measurement is equal on port and starboard.

Adjusting and tuning a sailboat rig will often bring benefits such as easier handling and better performance.

Next do the same for the cap shrouds, these are the ones that go to the top of the mast, but note that due to the length of the shrouds, it is easy to bend the mast to either port or starboard. With the shrouds adjusted, sight up the mast one more time to ensure that it is still straight.

Next comes the fore and aft adjustment, which is made with the backstay and forestay. Masts should be plumb or lie back slightly. It should never rake forward. A good starting point is to tighten up the forestay and backstay a little over hand-tight. Use the main halyard as a plumb bob. Cleat off the halyard so the free end is just clear of the top of the boom and let it hang. If the shackle on the end of the halyard hits the mast, the mast is likely too far forward, so slacken off the forestay and tighten the backstay. Adjust a little at a time until the end of the halyard hangs free — 4 or 5 inches is a good starting point.

You'll need to install cotter pins into the turnbuckles to prevent them loosening over time, but before doing that, take the boat for a sail when the wind is blowing about 10 knots and see how everything works. With the boat on a beam reach, note the tightness of the windward shrouds. If they appear slack, they will need to be adjusted up. If the boat is hard on the tiller or wheel and tries to turn into wind, the mast has too much aft rake, so you'll want to slacken the backstay and tighten up on the forestay a little. If the bow wants to turn away from the wind, the mast is too far forward, so you'll need to move the mast back a little.

If you are at all unsure about tackling this task, play it safe and smart — seek out the services of a qualified rigger who has access to rig tension gauges and other specialized tools.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

Contributing Editor, BoatUS Magazine

A marine surveyor and holder of RYA Yachtmaster Ocean certification, BoatUS Magazine contributing editor Mark Corke is one of our DIY gurus, creating easy-to-follow how-to articles and videos. Mark has built five boats himself (both power and sail), has been an experienced editor at several top boating magazines (including former associate editor of BoatUS Magazine), worked for the BBC, written four DIY books, skippered two round-the-world yachts, and holds the Guinness World Record for the fastest there-and-back crossing of the English Channel — in a kayak! He and his wife have a Grand Banks 32.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

The Worldwide Leader in Sailmaking

- Sail Care & Repair

- Sailing Gear

- Find A Loft

- Sail Finder

- Custom Sails

- One Design Sails

- Flying Sails

- New Sail Quote

- 3Di Technology

- Helix Technology

- Sail Design

- AEROTECH Spinnaker Cloth

- NPL RENEW Sustainable Sailcloth

- Sailcloth & Material Guide

- Polo Shirts

- Sweaters & Cardigans

- Sweatshirts & Hoodies

- Accessories

- Shop the look

- Mid & Baselayers

- Deckwear & Footwear

- Luggage & Accessories

- Fall Winter '24

- North Sails x 37th America's Cup

- Sailor Jackets

- SALT X North Sails

- NS x Slowear

- T-shirts & Tops

- Sailor Jacket

- Sustainability

- North Sails Blog

- Sail Like A Girl

- 37th America's Cup

- Icon Sailor Jacket

- Our Locations

- Certified B Corporation

- North SUP Boards

- North Foils

- North Kiteboarding

- North Windsurfing

SAIL FINDER

SAILING GEAR

COLLECTIONS & COLLAB

COLLECTIONS

WE ARE NORTH SAILS

ACTION SPORTS

Popular Search Terms

Organic cotton

Scuba fleece

Drawstring hood

Utility pocket

Stand collar

Sorry, no results for ""

Subscription

Welcome aboard.

We want to make our emails as relevant as possible for you.

Interests saved

Something went wrong, please try again

Welcome to North Sails

Stay up to date with the latest North Sails news.

Receive a 10% discount code for your first apparel order. Excludes sails and SUP’s. See our Terms and Conditions .

Yes, I agree to the terms of use and privacy policy.

HOW TO TUNE YOUR RIG

Without a properly tuned rig, you won’t be able to control your mast’s behavior over the full range of conditions. Fortunately, rig tuning is a straightforward step by step process for both masthead and fractional rigs.

The goals in rig tuning are the following: (1) Eliminate side bend and lean, (2) Set mast rake for proper helm balance, (3) Set pre-bend to match the mainsail design, and (4) Control mast bend and headstay sag.

Here are a few definitions and explanations to get us started.

GET IN TOUCH

REQUEST A QUOTE

BROWSE ALL SAILS

FIND YOUR SAIL

Featured stories, offshore sailing guide, how to care for your foul weather gear, npl renew faq.

- Refresh page

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sails and Rigging

- Maintenance

- Sailing Totem

- Sailor & Galley

- Living Aboard

- Destinations

- Gear & Electronics

- Charter Resources

- Ultimate Boating Giveaway

How to Inspect and Tune a Sailboat Rig

- By Ralph Naranjo

- Updated: May 14, 2020

Major mast failures usually begin as minor hardware problems. At least that’s what scrap-bin forensics seems to confirm. So, instead of dreading a dismasting, prevent it with a sensible approach to rig maintenance.

Some sailors inspect their masts and rigging with the spar stepped, but most recognize how much will remain unseen. Riggers recommend that the mast come out every few years and be placed on a pair of sturdy sawhorses ready for close-up scrutiny. My DIY approach focuses on hardware junctions and points where load paths intersect. Packed in my rigger’s bag are the usual hand tools, plus a Scotch pad, a quality magnifying glass and a small digital camera to record the findings. The old rule of thumb is that standing rigging has a decade’s, or one circumnavigation’s, worth of reliability; it’s a benchmark that remains valid today.

Another important issue is the rigging’s designed safety factor, or how much stronger the components are than they need be. The catch here is material deterioration over time, and the fact that there’s a direct correlation between stronger structures and increased reliability. For example, by increasing 1-by-19 shrouds and their attendant hardware from 5/16 inch to 3/8 inch, the higher safe working load translates into a longer life span. It’s a legit assumption, but doing so is both costlier and adds weight aloft, which can rob performance. The same tenets apply for a larger-diameter spar section and greater wall thickness. Engineers and naval architects try to balance these competing factors.

Some decades ago, I watched the deck-stepped spar of my first little cruising sloop drop into the drink. It drove home the fact that it really is the little things that count. In that case, it was a stainless- steel toggle, connected to an upper shroud turnbuckle, which had endured a few too many on-off load cycles. A tiny, nearly invisible crack had opened up, and salt spray had found a new home. The resulting corrosion tipped the scale and led to a dramatic failure. Since then, rig scrutiny has become my obsession.

The old rule of thumb is that standing rigging has a decade’s, or one circumnavigation’s, worth of reliability.

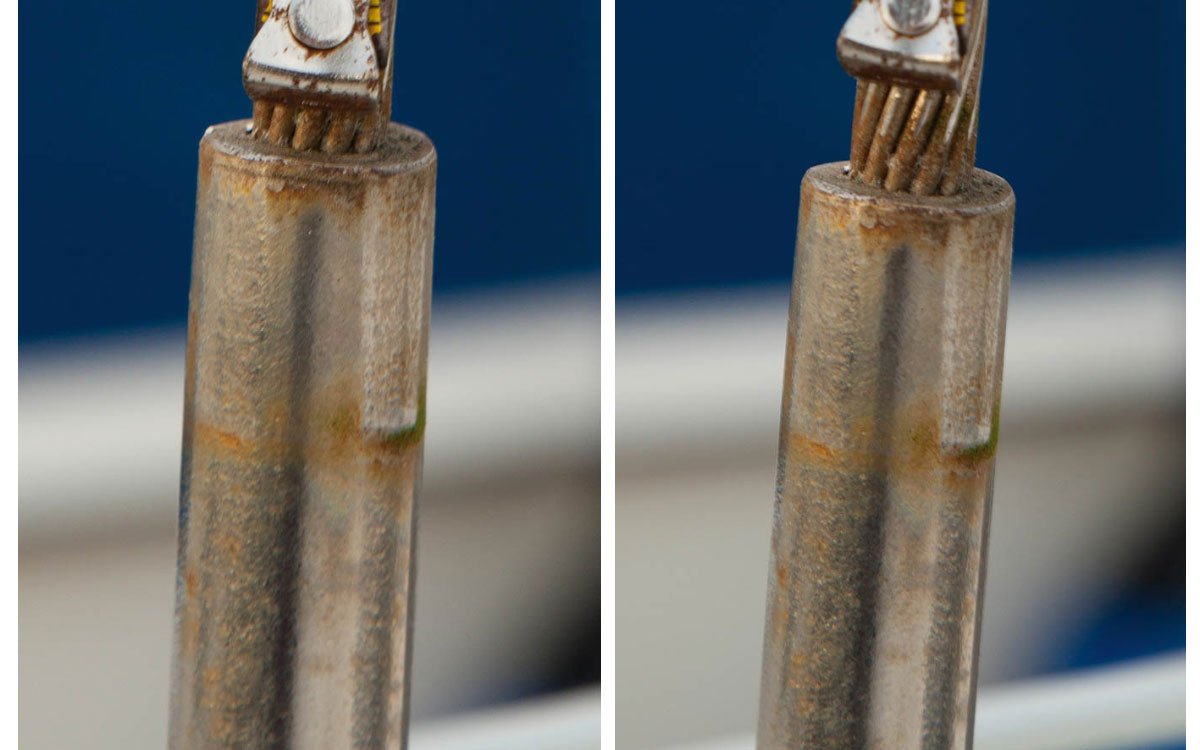

Wire and rod end fittings need a close look, especially in areas where there are brown stains and signs of cracks, pitting or other surface deterioration. This includes an evaluation of clevis-pin holes that should be circular, not elongated. Confer the same level of scrutiny to the clevis pins themselves. Don’t confuse stainless-steel clevis pins with chrome-plated bronze pins. The latter are just fine when used in bronze fittings, but when a bronze clevis pin is placed in a stainless-steel chainplate hole, the bronze pin can be carved away by the much harder stainless-steel chainplate.

My inspection process includes a rigging-wire wipe-down with a rag that easily snags on tiny cracks. It includes careful scrutiny of hardware junctions. I search for signs of chafe, especially where fiber or wire running rigging makes directional changes at sheave boxes, and around where the headsail furler’s top swivel rides. Looking closely at masthead exit points, I check for sheave wobble, excess side play and signs of pulley damage.

This is also the time to sort out halyards that are rubbing against external or internal obstructions. I use a bright, narrow-beam LED flashlight for a good visual inspection of the internal portion of the mast. Not only will it pinpoint screws and sheave boxes that might be causing chafe, but it also will help you untangle crossed halyards and confirm fairleads. While working at the heel end of the spar, look closely for corrosion and a condition riggers call “elephant foot.” It’s an actual wrinkling of the alloy tube section caused by too much compression and a too-thin wall section. It’s most often seen on raceboats with powerful hydraulic mast-adjusting systems, and on cruising boats that have pounded into too many steep wave faces.

Roller furling foils hide the wire or rod on which they spin. Rigging end fittings and terminals can usually be inspected, but a broken strand of wire inside the foil might initially go unnoticed, at least for a little while. This is another reason why offshore cruisers opt for a cutter or solent rig that adds a second stay for some extra insurance. Following the once-a-decade rule, it makes sense to completely disassemble furling systems, and replace the wire along with any worn bearings, bushings or plastic spacers.

My inspection process includes a wire wipe-down with a rag that easily snags on tiny cracks. I search for signs of chafe everywhere.

Keep in mind that when the mast is unstepped, many roller furling drums and head foils (especially on boats with deck-stepped rigs) extend beyond the heel of the spar. If the yard doesn’t splint and immobilize the extended foil and drum, do it yourself. All it entails is a couple of 2-by-4’s, or a pair of old oars lashed or duct-taped to the mast just above the heel. This double splint should extend to the base of the roller-furling drum where it too is lashed or taped. It keeps the drum from dangling and bending the foil during transport, and while the rig is stored on a mast rack.

Spreaders also deserve a really close look. All too often, excess anti-chafe protection results in the spreader tips becoming a water trap that turns into a hidden corrosion bath. So, when the rig is down, cut away the spreader-tip padding, and use white vinegar and a plastic scrub pad to get rid of any white powdery oxidation. Remove the spreaders from the spar, and inspect the area where spreader bases make contact with the mast. Look for compression damage to the mast wall and signs of corrosion damage. If all is well, reassemble using one of the tried-and-proven water-resistant lubricants. I’ve settled on Lanocote, McLube Sailkote and Super Lube, using Boeshield T-9 and WD-40 as my go-to spray protectant and penetrant. Throw away the old cotter pins, and use new pins on all of the reassembled rigging.

“She’ll be right, mate,” was the favorite phrase of an old Kiwi friend, but it isn’t good advice when it comes to keeping the rig where it belongs. Don’t shy away from calling in a qualified rigger to handle larger problems.

Most boatyards will restep spars but won’t tune the rig. Their goal is to set up the mast and rigging to approximate how it arrived. Occasionally, they hit the mark and even replace the mast wedges appropriately. Otherwise, I wait for a flat calm to make sure that the boat has no list. This involves using a tape measure to confirm the athwartship trim (waterline to rail-height port equals waterline to rail-height starboard). Then I check the perpendicular and rake of the mast using the main halyard with a makeshift plumb bob (dive weight) attached. The retune requires loosening the turnbuckles and incrementally retensioning the rigging. Small amounts of headstay and backstay adjustment relocates the masthead, causing the makeshift plumb bob to move significantly. I use prior measurements from previous mast-tuning successes to set the rake to a sweet spot that, in the past, delivered a minimal amount of weather helm.

With the rake set, I insert a set of teak or high-density hard-rubber wedges between the mast and the mast partners. These wedge-shaped spacers have a top flange that prevents them from falling into the bilge when the mast compresses on one side of the partners and opens the gap wider on the other. With all the wedges set, I incrementally add tension to the rig, tightening headstay and backstay first, while carefully maintaining the rake angle. Next, I adjust the upper shroud (or V1), working from side to side to keep the mast perpendicular. Finally, I snug up (but not overtension) the lower and intermediate shrouds. This static tuning sets the stage for an underway final tune, during which I check how well the spar remains in column. Leeward bends and S-curves are problematic and must be minimized. Boats with discontinuous rigging have shrouds that are not one continuous wire run. They utilize turnbuckles located above spreaders that must be individually adjusted to eliminate side bend.

During sea trials, make sure the leeward standing rigging is not overly slack and flopping around like loose spaghetti.

Intentional fore and aft mast bending can influence sail shape, and is put to good use aboard raceboats. Adding such complication to most cruising boats, which are normally steered by an autopilot, makes less sense. In-mast furling spars are least happy with powerful hydraulic backstays bowing the mast. So, get sound advice from a rigger/mast builder before adding hydraulic sail-shaping gear.

A sea trial should follow your static mast tune. And as you beat to windward in a modest 10- to 15-knot true breeze, check the leeward standing rigging. Make sure it’s not overly slack and flopping around like loose spaghetti. If so, add more shroud tension to both sides. A tension-testing gauge will work, but many sailors do fine estimating by hand. Cruising-boat rigs shouldn’t have the same amount of rig tension as a raceboat beating to windward. However, if your sailboat’s mast is deck-stepped, make sure the coachroof isn’t deforming due to the compression load. A compression post, ring frame or other rigid structure should be spreading such loads. If you’re unsure of the correct rig tune, arrange a session with a rigger or sailmaker—and start the season in optimized trim.

Technical expert Ralph Naranjo has inspected the rig on his Ericson 41, Wind Shadow , on countless occasions.

- More: fitting out , hardware , How To , mast , rigging

- More How To

Grease the Wheels of Your Boat: A Guide to Proper Lubrication

A Bowsprit Reborn: A DIY Renovation Story

Rigging Redo: Our Switch to Synthetic

Top Tools for Sailboat Cruising: Must-Have Gear for 2024

Galápagos: A Paradise Worth the Paperwork

Around Alone

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

How to tune your rig for optimal performance

Optimizing the performance of your boat's rigging system is crucial for an enjoyable and safe sailing experience. This guide provides step-by-step instructions for tuning your rig and maintaining your sails.

How to Tune Your Rig for Optimal Performance

Sailing is an art that requires constant learning and adaptation. One of the most important aspects of sailing is ensuring that your boat’s rigging and sails are in top condition. In this article, we will discuss how to tune your rig for optimal performance, ensuring that you and your family can enjoy smooth sailing on your adventures.

Table of Contents

Understanding the basics of rigging, the importance of rig tuning, step-by-step guide to rig tuning, sail improvements for better performance, maintaining your rig and sails.

Before we dive into the process of rig tuning, it’s essential to understand the basics of rigging. The rigging system on a sailboat consists of various components, including the mast, boom, shrouds, stays, and sails. These components work together to provide stability, support, and propulsion for your boat.

Mast and Boom

The mast is the vertical pole that supports the sails, while the boom is the horizontal pole attached to the mast’s base. The mast and boom are critical components of your rigging system, as they provide the framework for your sails.

Shrouds and Stays

Shrouds and stays are the wires or ropes that connect the mast to the boat’s hull. They provide lateral and fore-and-aft support for the mast, ensuring that it remains stable and upright. Shrouds are typically attached to the sides of the boat, while stays are connected to the bow and stern.

Sails are the primary means of propulsion for a sailboat. They work by capturing the wind’s energy and converting it into forward motion. There are various types of sails, including mainsails, jibs, and spinnakers, each with its own unique characteristics and uses.

Rig tuning is the process of adjusting your boat’s rigging system to achieve optimal performance. Proper rig tuning can significantly impact your boat’s speed, handling, and overall sailing experience. Some of the benefits of rig tuning include:

- Improved boat speed and pointing ability

- Enhanced sail shape and efficiency

- Reduced wear and tear on rigging components

- Increased safety and stability

By regularly tuning your rig, you can ensure that your boat is always performing at its best, allowing you and your family to enjoy your sailing adventures to the fullest.

Rig tuning can be a complex process, but with the right knowledge and tools, it’s something that any sailor can learn to do. Here’s a step-by-step guide to help you tune your rig for optimal performance:

Step 1: Inspect Your Rigging

Before making any adjustments, it’s essential to inspect your rigging for signs of wear, damage, or corrosion. Check all components, including the mast, boom, shrouds, stays, and sails, for any issues that may affect your boat’s performance.

Step 2: Set Your Mast Rake

Mast rake refers to the angle of the mast relative to the boat’s centerline. Adjusting the mast rake can have a significant impact on your boat’s balance and performance. To set your mast rake, follow these steps:

- Attach a weight to your main halyard and let it hang freely over the side of the boat.

- Measure the distance from the halyard to the boat’s centerline at the chainplates.

- Adjust the forestay and backstay until the desired rake is achieved.

Step 3: Adjust Your Shrouds and Stays

Next, you’ll need to adjust your shrouds and stays to ensure proper mast alignment and tension. Follow these steps:

- Loosen all shrouds and stays.

- Tighten the upper shrouds until the mast is straight from side to side.

- Tighten the lower shrouds to remove any side-to-side play in the mast.

- Adjust the forestay and backstay to achieve the desired mast bend.

Step 4: Check Your Rig Tension

Proper rig tension is crucial for maintaining sail shape and boat performance. To check your rig tension, follow these steps:

- Attach a tension gauge to your shrouds and stays.

- Measure the tension in each wire, adjusting as necessary to achieve the desired tension.

- Ensure that the tension is even on both sides of the boat.

Step 5: Fine-Tune Your Rig

Once your rig is properly tensioned and aligned, you can make any final adjustments to optimize performance. This may include adjusting your sail controls, such as the outhaul, cunningham, and vang, to fine-tune sail shape and efficiency.

In addition to rig tuning, there are several sail improvements that you can make to enhance your boat’s performance. Some of these improvements include:

- Upgrading to high-quality sails made from durable, lightweight materials

- Regularly cleaning and inspecting your sails for signs of wear or damage

- Using sail battens to improve sail shape and efficiency

- Installing a roller furling system for easier sail handling and storage

By investing in these sail improvements, you can ensure that your boat is always performing at its best, allowing you to enjoy your sailing adventures to the fullest.

Regular maintenance is essential for keeping your rig and sails in top condition. Some maintenance tasks to consider include:

- Inspecting your rigging for signs of wear, damage, or corrosion

- Lubricating moving parts, such as sheaves and blocks, to reduce friction and wear

- Replacing worn or damaged components, such as shrouds, stays, and sails

- Regularly cleaning your sails to remove dirt, salt, and other contaminants

By staying on top of these maintenance tasks, you can prolong the life of your rig and sails, ensuring that your boat is always ready for your next adventure.

Tuning your rig for optimal performance is an essential skill for any sailor. By following the steps outlined in this article, you can ensure that your boat is always performing at its best, allowing you and your family to enjoy your sailing adventures to the fullest. Remember to regularly inspect and maintain your rig and sails, and don’t be afraid to make improvements and adjustments as needed. With the right knowledge and tools, you can transform your boat into a high-performance sailing machine that’s ready to take on the open sea.

How To Tune Your Sailboat Rig

- August 2, 2023

Table of Contents

Sailing, with its perfect balance of adventure and tranquility, has enchanted mariners for centuries. Whether you’re cruising coastal waters or vying for victory in a thrilling regatta, your sailboat ‘s performance hinges on a seemingly unassuming yet critical aspect: rig tuning. Understanding how to properly adjust the tension in your sailboat’s standing rigging is the key to unlocking the full performance of the boat. In this article, we delve into the art of sailboat rig tuning, exploring the reasons why it is not only important but fundamental to achieving optimal performance, safety, and overall sailing enjoyment.

Why Tuning Your Rig Is Important

Tuning your sailboat rig is essential for several reasons that directly impacts your sailboat’s performance, safety, and overall experience. Here are the main reasons why rig tuning is important:

- Sailing Performance: Properly tuned rigging ensures that the sails are set up optimally for various wind conditions. A well-tuned rig allows the sails to achieve their best shape, providing better lift and speed. It improves the boat’s pointing ability, acceleration, and overall sailing performance.

- Sail Shape and Balance: Rig tuning helps control the shape of the sails, allowing them to perform efficiently. The correct tension in the rigging ensures the right amount of luff tension on the headsail, preventing excessive sag and maintaining proper sail balance. This, in turn, results in better boat balance and easier handling.

- Safety and Durability: An improperly tuned rig can lead to increased stress on the rigging components, mast, and sail. Over-tensioned rigging can cause excessive loads, leading to potential failures or damage. Conversely, under-tensioned rigging can cause the mast to pump or the rig to be unstable in rough conditions. Proper tuning helps prevent rigging issues and increases the overall safety and longevity of the rig.

- Weather Conditions: Different wind conditions require adjustments in rig tension. In light winds, a looser rig allows for a fuller sail shape, while in heavy winds, a tighter rig flattens the sails and depowers the boat. Adjusting the rig to suit the conditions helps maintain control and optimize performance.

- Boat Balance and Helm Feel: Rig tuning affects the boat’s balance and how it responds to the helm. Properly tuned rigging ensures a balanced helm and a boat that tracks well, making it easier to steer and reducing fatigue for the crew.

Regularly checking and adjusting the rig ensures that your sailboat operates at its best, whether you’re cruising or racing. If you’re unsure about rig tuning, consider seeking advice from a professional rigger or an experienced sailor to help you get the most out of your boat.

Sailboat Rig Tuning Process

Tuning a sailboat rig involves adjusting the tension in the standing rigging (shrouds and stays) to achieve the correct balance and shape of the mast and sails. Here’s a step-by-step guide to help you tune your sailboat rig:

1. Check the Basics:

- Ensure the boat is level and upright, preferably in the water, with the mast straight.

- Check that all turnbuckles are free and not corroded or stuck.

2. Determine the Baseline:

- Refer to your sailboat manufacturer’s manual, sailmaker ‘s tuning guide, or rigging expert’s recommendations for the initial baseline settings of your rigging tension. This usually includes the recommended tension for the upper and lower shrouds and forestay/backstay.

3. Loosen the Rig:

- Loosen all the rigging turnbuckles to the point where they are free to move. This step allows you to start with a clean slate and avoids putting undue strain on the rigging while adjusting.

4. Center the Mast:

- Use a measuring tape or a specific mast rake measurement tool to ensure the mast is centered and straight on the boat, both athwartships (side-to-side) and fore and aft.

Closed Reel Long Tape Measure – Flexible Fiberglass Double Face Printing Inch/Metric

5. Adjust Shroud Tension:

- Begin by tensioning the lower shrouds to the recommended baseline tension. Use a tension gauge, Loos gauge, or tensiometer to achieve the desired tension. Repeat this process for both sides of the boat.

- Next, adjust the tension in the upper shrouds to match the recommended baseline tension. Be careful not to overtighten any of the rigging.

Spinlock Rig Sense Tension Gauge for 2-5mm Wire

Sailboat Rigging Tension Gauge from Loos & Co., PT-2 Professional Hands-Free Force Gauge Up To 2,000 lb

Sailboat Rigging Tension Gauge from Loos & Co., PT-3 Professional Hands-Free Force Gauge Up To 4,500 lb

6. Check Mast Bend:

- Securely, attach the main halyard to the lowest point on the rear base of the mast. From there, tighten the main halyard until there is a fair amount of tension on it. The main halyard represents a straight line which is the base line for your measurement. If there is mast bend present, there will be a gap between the main halyard and middle of the mast at its furthest bend point. This gap is what is to be measured for your mast bend measurement.

7. Check Mast Rake:

- Mast rake refers to the fore and aft angle of the mast. It can impact boat balance and helm feel. Use a mast rake measurement tool or reference marks on the boat to adjust the mast rake as needed, following the manufacturer’s recommendations or your sailmaker’s advice.

8. Check Forestay Tension:

- Adjust the forestay tension to achieve the desired amount of luff tension on the headsail. For sailboats with adjustable backstays, make sure your backstay off off when taking this measurement. For boats with a fixed backstay, a proper forestay tension ensures proper sail shape and minimizes sag in the forestay.

9. Tune the Backstay:

- If your boat has an adjustable backstay, adjust it to control the bend in the mast and headsail shape. More tension on the backstay usually flattens the mainsail and depowers the rig, while less tension allows for a fuller sail shape.

10. Fine-Tuning:

- Go sailing and make small adjustments to the rig while underway to achieve the best sail shape and performance. Pay attention to how the boat behaves in different wind conditions and adjust the rig accordingly.

11. Periodic Checks

- Rig tuning is not a one-time task. Check your rig regularly for any changes due to sailing conditions, mast compression, or wear. Make adjustments as needed to maintain optimal performance.

It’s essential to keep a record of your rigging settings and changes so you can refer back to them and fine-tune your rigging over time. If you’re unsure about tuning your rig, consider seeking advice from a professional rigger or experienced sailor.

The Sailor’s Marketplace for Sailboats and Sails.

Sell Your Sailboat

Sailboats for sale.

- New Sailboats

- Used Sailboats

- Cruising Sailboats

- Racing Sailboats

Sell Your Sails

Sails for sail, sail manufacturers.

- North Sails

- Quantum Sails

- Doyle Sails

- UK Sailmakers

Sailing Reviews

- Sailing Line

- Safety Equipment

- Sailing Accesories

As an Amazon Associate SailTrader earns from qualifying purchases.

This website uses cookies to ensure you get the best experience possible.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Catalina 270 vs. The Beneteau First 265 Used Boat Match-Up

Ericson 41 Used Boat Review

Mason 33 Used Boat Review

Beneteau 311, Catalina 310 and Hunter 326 Used Boat Comparison

Tips From A First “Sail” on the ICW

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Thinking Through a Solar Power Installation

Polyester vs. Nylon Rode

Getting the Most Out of Older Sails

How (Not) to Tie Your Boat to a Dock

Stopping Mainsheet Twist

Fuel Lift Pump: Easy DIY Diesel Fuel System Diagnostic and Repair

Ensuring Safe Shorepower

Sinking? Check Your Stuffing Box

The Rain Catcher’s Guide

What Do You Do With Old Fiberglass Boats?

Boat Repairs for the Technically Illiterate

Boat Maintenance for the Technically Illiterate: Part 1

Whats the Best Way to Restore Clear Plastic Windows?

Giving Bugs the Big Goodbye

Galley Gadgets for the Cruising Sailor

Those Extras you Don’t Need But Love to Have

What’s the Best Sunscreen?

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

How to Select Crew for a Passage or Delivery

R. Tucker Thompson Tall Ship Youth Voyage

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

On Watch: America’s Cup

On Watch: All Eyes on Europe Sail Racing

Dear Readers

- Sails, Rigging & Deck Gear

Boat Clinic: Tuning the Masthead Rig

My father was a rarity: he really did not care at all how well the boats he sailed performed. Perhaps this was because, in his youth and young manhood, he had been both a tremendously aggressive and a wonderfully successful athlete and thus had wrung out his competitive needs.

Tuning the rig of a boat is one of the necessary -and pleasant -tasks which must be done to achieve good performance. In an untuned boat, the mast bends in odd ways, and this in turn causes the sails to set badly. By contrast, on a well tuned boat , the rig bends in a controlled fashion, allowing the sails to do their best. For this reason, an avid racer will be constantly fiddling with the tune of his boat, while for most of us a one time job during commissioning may suffice.

The first thing to realize is that for a mast to stand well, it should not be straight when in a static, no load situation. This was something I realized nearly thirty years ago when conventional advice was to tune rigs so that masts were indeed straight when static, and while that advice is still sometimes given, most of the sailing world has realized that a controlled static bend is needed.

The problem with a statically straight mast is that when loaded, it is too easy for the mast to invert, or bend backwards. This can happen when the boat is beating in a seaway or reaching with the spinnaker pole up. Most mast sections can accommodate a significant amount of forward bend without failure, but very little aft bend.

An afternoon spent on a poorly tuned boat a couple of seasons ago left me a nervous wreck. Each time the boat came off a wave the mast pumped and wriggled so much that you could see it changing shape from the tiller. The owner, happy man, was ignorant and oblivious to the danger of losing his rig.

In contrast, if you set up the rig so that it has “prebend”, that is, the center of the mast bends forward when in a static condition, the loaded mast will flex in the proper direction. What flex there is will then tend to flatten the main, rather than bagging it, and the boat should balance better, particularly in heavy air, when most boats start to develop helm problems.

The first job is to get the mast straight athwartships. Leave the lower shrouds hand slack during this procedure. Use the main halyard as a measurer. Take the shackle end of the halyard a measured distance aft of the bow along the gunwale, then have someone take up the slack while you hold the shackle firmly to that point. Cleat off the halyard.

Then take the end of the halyard to the same point on the other side of the boat. If the mast is straight athwartships, the halyard shackle will just kiss the same point on the gunwale on either side of the boat.

Because chainplates are rarely put on perfectly symmetrically on the two sides of the boat, it is best to go to the trouble to measure back from the stemhead on each side for your reference mark, rather than using the chainplates as the reference.

If the halyard doesn’t touch the same point on both sides of the boat, adjust the cap shrouds (upper shrouds) until the mast is straight. Be sure to loosen one side as you tighten the other, and sight up the mast to make sure that you haven’t put any sideways bend in. The sailtrack should be straight athwartships when you sight up the mast, unless it has been put on crooked.

It should be noted that if your deck is slightly crooked -a fairly common problem the mast may not be perfectly centered athwartships in the partners when it is vertical to the hull.

Don’t attempt to make the mast vertical by putting a level on the side of the mast. Almost no boat floats without a list to one side or the other, and your weight alone is enough to put a slight list on a surprisingly large boat.

At this point, on boats up to about 35’, the cap shroud turnbuckles should be hand tight. What’s hand tight? Just what it says: as tight as you can get a well-lubricated turnbuckle with your bare hands. Later, when testing under sail, you’ll find the leeward shrouds slopping around by a few inches; then, and only then, you can take the slack out of the leeward shrouds. If you have absolutely no slack in the leeward capshroud when the boat is going upwind in 1.2 knots of wind, the shrouds are probably too tight for most boats.

Next set the rake of the mast using the fore and back stays, again only hand tight. If you don’t know from experience what the proper rake should be, begin with a modest rake of no more than the fore and aft diameter of the mast. Use the main halyard as a plumb bob. Later you may wish to modify this rake. Utilize the facts that increasing mast rake and/or moving the mast aft increase weather helm,-while decreasing mast rake and/or moving the mast forward decrease weather helm.

Now that the mast is properly straight athwartships and properly raked, it’s time to start the controlled bends. These are accomplished with the forward lowers, babystay, backstay, and mast wedges. Whether your boat has double forward lowers or a single, centerline babystay doesn’t matter. Both systems accomplish the same end.

First, take up the babystay or double forwards until you’ve pulled a forward bend of 1/2” to 1” into the middle section of the mast. Again use the main halyard -this time pulled tight against the lower, aft edge of the mast -as a measuring reference. If using double lowers, make sure the mast remains straight athwartships.

Next crank up on the backstay until you’ve got a curve in the mast equal to 1/2 to 1 times the fore and aft dimensions of the mast. Finally, take up the aft lowers hand tight.

If your mast is stepped on the keel you need at this point to wedge it at the partners. Wooden wedges are easiest to make, but they can dent an aluminum mast if the shrouds are set so loosely that the mast leans to leeward significantly when sailing upwind. A fairly firm rubber wedge works better with looser rigs, and is probably the safest to use. Rubber wedges are usually harder to make, however.

Your boatyard or chandlery may sell special rubber for mast wedges. If not, try to buy something in the nature of thick inner tubing. In a real pinch, sections cut from old auto tires will do, but will have to be rasped to thickness. Don’t use a foam material; it’s too soft. You’ll need two wedges, one fore, one aft. The width of each should be about 35 % to 40% of the mast’s circumference. Thus, they’ll curve around both the front and sides of the mast. Since the rubber wedges must be under compression, their thickness should be slightly greater than the gap they need to fill. You may have to cement together several layers of thin rubber to achieve the proper thicknesses.

The first step in wedging is to trim the wedges so they do not push the mast out of column sideways. As noted earlier, many decks are slightly off center, so there may not be equal space on both sides of the mast, even when it is in the proper position.

When the wedges are properly trimmed for the sides of the partners, you are ready to insert the aft wedge. To support the prebend, put a line around the mast a foot or so above the partners, and run it forward to a fixed point -a snatch block on a mooring cleat or a bridle between the cleats -then aft to a cockpit winch. Now slip the aft wedge into place. Release the load on the line, and insert the forward wedge. A little soap on the wedge will ease a tight fit.

Now you’re ready for a sailing trial.

Choose a day when you can comfortably carry a genoa. About eight to 1 5 knots of wind will do for most boats.

Put the boat hard and full on the wind and check the mast. It should be retaining the same fore and aft curve you put in while tuning. If not, adjust the babystay or forward lower shrouds. Next check the athwartships shape of the mast. It should be straight. Any necessary adjustments should be carried out with the leeward shrouds, then the boat should be tacked to check the effect of the adjustments.

If the mast is straight athwartships, tack and hand tighten all the leeward shrouds by an equal number of turns. If the center of the mast bends to weather, tighten the capshrouds more than the lowers. If the center of the mast sags to leeward, tighten the lower shrouds more than the cap-shrouds.

You should also check the athwart-ships bend of the mast in varying wind strengths, adjusting the aft lowers until you’ve achieved the best compromise between a straight mast and one which falls off or hooks. A masthead which hooks to windward should be avoided.

When, after a few sailing trials, you’re satisfied, pin the turnbuckles, then tape everything that could catch a sail or sheet.

We’ve dealt with what might be called traditionally rigged masts, those with spreaders which sprout essentially at right angles to the mast. Nothing we’ve said, however, isn’t also true of fractional rigs with aft raked spreaders. The only difference is that on such a rig the cap shrouds, as they load up, work on the spreaders to increase forward mast bend, but that’s all to the better.

– J. Pazereskis

RELATED ARTICLES MORE FROM AUTHOR

Working with High-Tech Ropes

Getting a Clue for the Blown-Out Clew

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos

Hans Christian 41T – Boat Review

Seven dead after superyacht sinks off Sicily. Was the crew at...

What’s the Best Sailboats for Beginners?

Why Does A Sailboat Keel Fall Off?

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

What You Need to Know About Rig Tune & Performance

March 18, 2022 Updated August 8, 2024

For many sailors, the relationship between rig tune and performance often seems like a black hole. Quantum’s Dave Flynn takes us on a tour of the core elements of the rig and what you need to know to demystify tuning for optimum performance.

Mastering rig tuning for optimal sail trim and performance might seem daunting, but fortunately it’s not as complicated as tuning a Stradivarius violin! To keep it in perspective, remember you are just pulling on a hunk of aluminum or carbon with cables. To master the rig, there are four elements you need to understand: rake, athwartship tuning, mast bend, and headstay sag. Each of the four elements of rig tune either adds power or takes it away. If you understand the basic mechanics of each element, you can tune your rig to improve trim and overall setup.

Mast rake is a measure of how far the mast is angled aft from a straight vertical. A typical mast rake ranges from one to one-and-a-half degrees on a cruising masthead rig to as much as four degrees on a fractional racing rig. A mast should never be raked forward unless there is something unusual in the boat design (you’ll know if this is the case!). When you add rake to the mast, you tilt the whole sail plan aft. This, in turn, shifts the power aft, pushing more load on the stern and forcing the bow up into the wind, creating weather helm.

Rake is determined by headstay length: The longer the headstay, the greater the rake. To adjust your rake, adjust the length of the headstay. How much rake a boat needs to generate the right amount of weather helm is a function of hydrodynamics (hull form, keel shape, and placement). In most one-design racing classes, where lots of time is invested in figuring out what works best, tuning guides specify headstay lengths for conditions. In more developed classes, this will change as a function of wind speed. You’ll want more rake in light air when it is hard to generate helm and less as the breeze builds. For boat setup and trim, adding rake is a tool for generating power in light air, and reducing rake is part of the de-powering process in heavy air.

For cruisers and many non-one-design rigs, you likely don’t have a tuning guide to work from, so to optimize upwind performance you need some helm loading in light-to-moderate conditions. Three to five degrees of rudder angle in 8kts-10kts of wind is a commonly cited target. To test if this angle works for you, sail upwind in 8kts-10kts and let the helm go; the boat should turn gently into the wind. If it goes straight or bears off, you need more rake and vice versa if it spins out of control. Don’t try this test when it is windy; your boat will round up and exhibit too much helm due to heel not rake, and you’ll get a false read.

ATHWARTSHIP TUNING

If the rig is not centered, performance and trim will be different tack to tack. To remedy this, center the top of the rig. Using the diagonal shrouds, bring each successive panel in line with the top. The amount of tension you need is tough to predict at the dock–the mast really needs to be under load. Test tension by sailing upwind in 10kts-12kts of breeze with appropriate trim settings and then check the mast. Is it straight when you put your eye to the aft face and look up the mainsail track? If the tip is falling off, you need more upper tension. If the leeward upper shrouds are flopping around, you need more tension for a given velocity. The shrouds should be firm.

Work on the diagonals next. How much tension you need in the leeward diagonals is determined by how stiff the mast is. In over 10 kts, you definitely want the mast to be straight. For more power in light air, you can let the middle of the mast sag an inch or two to leeward to increase the depth in the mainsail. It is common in one-design classes to ease tension on the diagonals in light air to create this smooth sag.

Dinghies and small keelboats are great boats to experiment with how tuning inputs affect your sail plan. The smaller diameter wire shrouds and relatively small masts dramatically show the impact of tuning adjustments. This isn’t as visible on larger racing or cruising boats with rod rigging. Cruisers will want to set a good base athwartship tune as well. If the rig is uneven side-to-side, you will experience frustrating differences in point and power on each tack. Skip the headache and set a good base tune early in the season. Whatever the condition you are sailing in, once you have established good upwind trim, have a look up the mast to make sure it is in column or sagging slightly to leeward in the middle in light air.

If you have an older cruising boat with a mast stiffness that resembles that of a telephone pole, you can skip this section! But for cruisers with a relatively modern rig, swept-back spreaders, traditional sails with flaking system, or even in-boom or in-mast furling, pay attention here.

While rake is the amount the mast is angled aft, mast bend is the amount you bend the mast aft after you have set your rake. A rig that bends gives you a powerful tool for changing the shape of the mainsail: More mast bend flattens the sail and de-powers it; a straighter mast creates shape and power. Rig tune affects how much a mast bends, particularly on modern fractional rig boats with swept back spreaders. But no matter what type of rig you have, you want to start with a little mast bend, or pre-bend, which refers to the amount of bend that has no backstay tension. Lengthening the headstay increases the bending moment and adds pre-bend. This is why it’s important to set the rake first. Other factors affecting the pre-bend are the position of the mast step and the blocking of the mast in the partner, which is the hole where the mast goes through the deck. To add pre-bend, either move the mast step aft or move the mast forward in the partners. A target of 1”-3” of pre-bend is typical on a medium-sized boat. Pre-bend ensures the mast will move forward in the middle and flatten the mainsail when you pull on the backstay.

On a rig with in-line spreaders (typically masthead rigs), the side shrouds have little impact on the mast bend created by pulling on the backstay. On some rigs, however, there are check stays to keep the mast from bending too far. Sometimes there are even multiple sets.

How far is too far when bending the mast? You’ll know when your mainsail develops diagonal wrinkles from the clew up to the luff and is beginning to turn inside out. For maximum de-powering, bend just to the point where wrinkles appear. If available, use check stays to help.

On modern fractional rigs with spreaders swept well aft, the side shrouds have a big impact on mast bend. The diagonal shrouds are controlling not only athwartship tuning but also acting like check stays to inhibit mast bend, since they are swept back and pulling aft. Too tight, and the diagonal shrouds will keep the mast from bending and flattening the mainsail; too loose, and the mast can over-bend and turn the sail inside out. In many classes, overall rig tension is increased by taking turns on the shrouds, shortening the headstay, or pumping the whole rig up with a mast jack for more backstay tension without allowing the rig to over-bend as it gets windier.

HEADSTAY SAG

If some mast bend is good, why isn’t more better? The answer is headstay sag. When the headstay sags, the headsail becomes full and more powerful, which is great in light conditions. But as the breeze builds, you want to reduce the amount of sag as much as possible to de-power the boat and help with pointing. In breeze, it’s all about headstay tension–you can’t get too much. So why is mast bend a factor? When you pull back on the rig with the backstay, it will tighten the headstay, which is good. But you are also pulling down and compressing the rig, which makes it bend. You want some mast bend in order to flatten the mainsail, but not so much that you soften the whole rig and increase headstay sag. This is why we use check stays to control mast bend on a masthead rig and tighter diagonal tension on a swept aft spreader rig.

Rig tune still matters even when you aren’t routinely adding turns to your shrouds based on the wind and conditions. Many modern cruising sailboats with in-mast furling rigs have comparatively smaller tune adjustments, as the rig needs to stay in column for the mainsail to furl properly. Some boats are outfitted with a cascading backstay adjuster that allows for minor tweaks and lets you easily reset the rig when it’s time to furl the mainsail. To get the most performance from your cruising setup, don’t overlook rig tune. Racing sailboats often have their rigs removed for transport and then re-rigged, whereas many cruising boats may never have had the rig adjusted since the boat was first commissioned. If you can't remember the last time your rig was tuned, now is a great time to give your local loft a call.

Having a properly tuned rig is essential to boat setup and performance. While this can be a DIY process, if you have questions or need additional input, please contact a professional rigger or your local loft where our expert Quantum team can help sort out your rig and tune. For one-design tuning guides and resources, select your OD class on the Quantum website or get in touch with a Quantum Class Expert.

Get in touch with David Flynn with additional questions and dive deeper into rig tune for performance. E: [email protected] P: 410-268-1161 ext. 206

The Discussion

This website uses cookies and collects usage statistics. Privacy Policy

Us, too. We pour that passion into each of our newsletters to help you enjoy sailing even more.

- Inshore Fishing

- Offshore Fishing

- Download ALL AT SEA

- Subscribe to All At Sea

- Advertising – All At Sea – Caribbean

Sail Rig Tuning – A Quick How To

You know you want it...

Mocka Jumbies and Rum...

Last month we started looking at sailboat rigging ( Sail Rig Inspection – A Quick How To ), namely how to inspect it to ensure that you enjoy your days on the water worry-free. Once sure that the rig is sound, you can focus on making it perform, and that’s where we pick up this month – sail rig tuning.

A Quick How To on Sail Rig Tuning

A complete sail rig tune involves a static tune at the dock AND a dynamic tune under sail.

How to do the Static Sail Rig Tuning

The static tune ensures everything is straight and true, while the dynamic sail rig tune sets it all up while the boat is under load.

TIP: Always grease and mark turnbuckle threads before adjusting them (to lubricate and establish a starting point).

At the dock, de-tune the athwartships shrouds – slacken upper shrouds more than the lowers. If the yacht has a backstay adjuster, ease it off completely.

Ensure that the mast is standing true by running a metal measuring tape up the sail track with a spare sail slide – from the masthead, measure down to the port and starboard chainplates. If the measurements aren’t equal, carefully adjust the upper shrouds to tilt the mast to port or starboard.

By hand, take up the shrouds symmetrically, uppers first. Sight up the mast track after each adjustment to ensure the mast remains ‘in column,’ without any bends. It’s amazing how accurate your eyes are in this case – trust them. A bend to port at the spreaders, for example, requires more tension on the starboard lower shroud, less on the port.

With large wrenches, carefully tighten the turnbuckles (again, symmetrically, uppers first) to the working shroud tensions. Uppers should be tightest – lowers and intermediates slightly less so. Always use the same arm when checking tension – touch is sensitive enough to notice an unbalance. An over-tensioned rig can indeed bend a fiberglass hull, so be conservative.

How to do the Dynamic Sail Rig Tuning

For the dynamic tune, sail close-hauled in a moderate breeze (12-18 kts). The leeward shrouds should be loose but not slack. Snug them up by hand (count your turns), then tack and do the same on the other side. The mast should remain in column throughout – new bends are best resolved back at the dock.

TIP: Backstay tension determines headstay tension – the jib luff should not have more than 12-18 inches of ‘deflection’ off centerline (most furlers will not furl smoothly if there is any more).

Secure each turnbuckle with new cotter pins, and re-check the rig each time you sail.

Don't Miss a Beat!

Stay in the loop with the Caribbean

LEAVE A REPLY Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Notify me of follow-up comments by email.

Notify me of new posts by email.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Antiguan Sailor Scores McIntyre Ocean Globe Race Win as Crew of Maiden UK

Usa’s montagu wins 31st international optimist regatta – st. thomas, us virgin islands, puerto rico’s mariner sailboat fleet gains popularity along south coast, so caribbean you can almost taste the rum....

Recent Posts

Bilge pump, period, caribbean coral reefs can recover better with rhythm, exciting new developments underway at camper & nicholsons’ port louis marina in grenada, recent comments, subscribe to all at sea.

Don't worry... We ain't getting hitched...

EDITOR PICKS

Talkative posts, the seven words you can’t put in a boat name, saying “no”, program for financing older boats – tips and suggestions, popular category.

- Cruise 1735

- St. Thomas, US Virgin Islands 497

- Caribbean 430

- Tortola, British Virgin Islands 423

All At Sea - The Caribbean's Waterfront Community Caribbean Cruising, Sailing, Boating, Fishing and Yachting

Contact us: [email protected]

© Kennan Holdings LLC - All Rights Reserved

Practical Boat Owner

- Digital edition

How to set up your rig: tension your shrouds on masthead or fractional

- David Harding

- March 15, 2021

How to set up three common types of rig: the traditional masthead with a single set of in-line spreaders, single-spreader swept fractional rigs, and fractional rigs with two sets of swept spreaders. David Harding reports

How to set up your rig : tension your shrouds on masthead or fractional

If boats were cars, many of those I see sailing along would be coughing and spluttering down the motorway at 35mph in third gear with three flat tyres and a smoky exhaust. Others would cruise past in top gear at 70, making half the noise and using a fraction of the fuel.

Would these top-gear drivers be working any harder? Would they have cars that were faster by design and more expensive? Not at all. They would simply be the ones who had pumped up their tyres, learned their way around the gearbox and had their engines serviced.

It’s worth keeping an eye on your leeward cap shrouds during early-season outings after the mast has been re-stepped. The ones on this yacht could do with a little more tension

The obvious question, then, is why so many boat owners seem to leave their quest for efficiency and economy on the dockside.

One answer is that many are unaware how inefficiently their boats are performing. Another is that there’s no MOT for sailing boats and no driving test to make sure people know how to sail them (thank goodness on both counts).

Whatever the reasons, the fact remains that an efficient rig is fundamental. If the rig’s not right, the sails have no hope of setting properly.

And that’s important whether you’re racing or cruising, because sailors of both persuasions ultimately want the same: maximum lift for minimum drag.

For racers, that means more speed and better results. They carry more sail because they have more crew to handle it and more weight on the rail to balance it.

Cruisers carry less sail but, if it works efficiently, it means less heel, less leeway, better pointing, less tacking, a lighter helm and greater comfort than if it’s working inefficiently – plus the ability to get home before night falls or the pub shuts. Who can object to that?

What matters is that the sail you’re carrying is driving you forwards, not pushing you sideways.

When I question cruising sailors about the state of their rig I often get the reply ‘Oh it doesn’t matter – I’m not racing!’.

Those I know who have done something about it, however, have been delighted by the transformation their boats have undergone and have had to agree that cruising fast and comfortably is definitely better.

Setting up your boat rigging

In this article we’re going to look at how to set up the three most common types of rig: the traditional masthead with a single set of in-line spreaders, single-spreader swept fractional rigs, and fractional rigs with two sets of swept spreaders.

For simplicity we’re assuming the use of 1×19 rigging except where mentioned otherwise.

Variations in boat rig type are almost infinite by the time you take into account deck-stepped and keel-stepped masts, masthead rigs with swept spreaders, jumper struts, fractional rigs with in-line spreaders, and so on.

Once you understand the basics, however, you’ll find that you can apply your knowledge to good effect on most types of rig.

Rig tuning is not only for the experts. Experience helps, of course, and a multiple-spreader fractional rig is harder to tune than an old tree-trunk of a masthead rig from the 1970s.

Nonetheless, with practice, a good eye and some observation you will probably find you can set it up pretty well.

You might want to call in a rigger or an experienced rig-tweaker to help or to do it for you the first time, and perhaps to check it periodically thereafter, but at least if you know what to look for you’ll notice when anything needs adjusting.

A word of warning when it comes to boatyards that have re-stepped your mast: sometimes re-stepping means just that and no more.

I have been on boats whose owners have assumed that the yard had set up the rig, whereas in fact it had just been dropped in and the bottlescrews hand-tensioned to stop it falling over.

It’s scary to think of the number of boats that must have been sailed in this condition.

What you will need to tune your rig Essential A calm day: don’t try setting up your rig in more than a few knots of wind A boat that’s floating level fore-and-aft (and preferably laterally as well) Screwdriver/lever bar Spanners (fixed or adjustable) Needle-nose pliers for split-pins Electrical insulation or self-amalgamating tape Lubricant for bottlescrews Tape measure (folding/small cassette type, or ideally folding rule) Useful Spring balance Long tape-measure Rig-tension gauge

The importance of enough tension: Why tight is right

If you think you’re being kind to your boat by leaving the rigging slack, think again. It’s true that some keelboats (such as Squibs and XODs) sail with the leeward cap shroud waving around in the wind, but that doesn’t work on yachts designed to go to sea.

Rigging that’s under-tensioned puts infinitely more load on the wire, bottlescrews, terminals and hull structure because of the snatch loads every time the boat falls off a wave. When it hits the bottom of the trough, anything that’s free to move gets thrown forwards and sideways before being brought up short by whatever happens to be in the way to stop it. That applies to the crew, to loose gear down below or to the mast. Think of the inertia to which a mast is subjected because of its height, and you can imagine the loads involved.

If the rigging is sensibly tight, on the other hand, movement and the consequent stresses are minimised.

Boats are built to withstand the static loads of a properly-tensioned rig, but asking them to cope with constant snatch loading is unfair – so don’t kill your boat with kindness.

As we discuss in the sections on the types of rig (below), masthead configurations with in-line spreaders need less cap-shroud tension than swept-spreader fractional rigs. This is because in-line caps are only supporting the mast laterally. The backstay stops it moving forwards, so each wire has a separate, clearly-defined role.

Aft-swept caps support the mast both laterally and fore-and-aft. Being swept aft typically about 25°, they need to be under a lot of tension to keep the forestay tight. Because they’re also at a much shallower angle to the mast, they bear between three and five times the load of the forestay.

With fractional rigs, then, it’s vital to keep the cap shrouds tight. If they’re too loose, the forestay will sag too much, the headsail will become too full and its leech will be too tight. Then the boat will become unbalanced, heel too far, make more leeway and lose both speed and pointing ability.

Structurally, under-tensioned rigging with a swept-spreader rig presents a problem in addition to the issue of snatch loading. Tension in the leeward cap shroud is important in keeping the mast in column, to the extent that Loos and Co (the manufacturer of the popular rig-tension gauges) states that a mast loses 50% of its lateral stiffness when the leeward cap goes slack. When this happens, the mast is effectively hinging around the forestay and the windward cap shroud and is far more prone to pumping as the boat bounces around.

The main reason why under-tensioned rigs on cruising boats stay standing as they do is that manufacturers build in enormous margins.

Even so, proper tension means better performance and greater safety. The ‘it doesn’t matter – I’m only cruising’ excuse for slack rigging just doesn’t cut it!

How to measure rig tension

This Loos gauge (left image) is indicating that the 6mm wire in the cap shroud is at 22% of its breaking strain (730kg). To measure the stretch, extend a tape measure (right) (or ideally a folding rule) to 2,000mm and mark this distance up the wire…

…but start with the end of the tape a couple of millimetres above the top of the swaging. As the wire is tensioned it will stretch, increasing the gap below the end of the tape.

Experienced riggers and rig-tweakers will often tension the rigging at the dockside by feel, then sight up the mast and make any adjustments under way.

Most people aren’t confident enough to do this, though – so what are the best ways to check the tension as you wind down the bottlescrews?

The simplest and quickest way is to use a rig-tension meter, such as the Loos gauge. Once you know the diameter of the wire, it will give you the load both in kg and as a percentage of its breaking strain.

The gauge for rigging of 5m and 6mm (and up to 14% of breaking strain on 7mm) typically costs around £65, while the bigger version for wire from 7mm to 10mm is closer to £200.

If you don’t have a tension gauge, you can calculate the percentage of a wire’s breaking strain by measuring its stretch, normally over a distance of 2m: when 1×19 wire has stretched by 1mm over a 2,000mm length, it’s at 5% of its breaking load whatever its diameter.

Most cruising boats have rigging made from 1×19 wire. On sportier boats, it might be Dyform or rod, in which case 5% of breaking load is indicated by stretch of 0.95 and 0.7mm respectively. For the purpose of our illustrations, we’ll assume 1×19.

For accurate measurement the rigging needs to be completely slack. Hold the end of the tape a couple of millimetres above the top of the swaging, then measure 2,000mm up the wire, secure the other end of the tape here and start tensioning. When the gap between the top of the swaging and the end of the tape has increased by 1mm, you have reached 5% of the wire’s breaking strain, so 3mm equates to 15% and 5mm to 25%.

Bear in mind that 1×19 wire will be affected by bedding-in stretch during its first few outings, so new rigging will need to be re-tensioned a time or two during the first season.

Sensible precautions 1. Don’t force dry bottlescrews: keep them well lubricated. 2. Don’t use massively long tools for extra leverage on the bottlescrews. If you can feel the load, you’re less likely to strain or break anything. 3. Most boats will flex to some extent when the rig is properly tensioned. If you’re concerned about excessive bend, take it easy, use a straight edge across the deck to check for movement, and seek advice. 4. The percentages of breaking load quoted assume that the rigging is of the correct diameter as specified by the designer, builder or rigger.

How to set up a masthead rig with single in-line spreaders

This is the simplest type of rig to set up. Whether it’s keel-stepped or deck-stepped and supported by forward lowers or a babystay, it’s the same basic procedure.

Step 1: Get the mast upright athwartships

Measure the distance to fixed points on both sides that are symmetrical about the centreline, such as the base of the chainplates.

If you don’t have a long tape measure, use the halyard itself (this is where a spring balance can help you gauge the same tension on each side).

Centre the masthead by adjusting the port and starboard cap shrouds until the measurements are the same, then hand-tighten the bottlescrews by taking the same number of turns on each side.

Re-check and adjust as necessary.

A long tape measure is useful for getting the mast upright.

Step 2: Setting the rake

Rake is determined principally by the length of the forestay. Some roller-reefing systems allow no adjustment but you can increase length by adding toggles.

Adjust the forestay and backstay, checking the rake with a weight suspended from the end of the main halyard. One degree of rake is about 6in (15cm) in 30ft (9m).

Hand-tight on the backstay’s bottlescrew (or gentle use of the tensioner) is fine at this stage.

Rake is measured from the aft face of the mast, at or below boom-level. If the boat’s rocking around, suspend the weight in a bucket of water to dampen the movement.

Step 3: Tighten the cap shrouds and backstay

Take no more than two or three full turns on one side before doing the same on the other.

Count carefully.

You’re aiming to tension the caps to 15% of their breaking strain, measured as explained on page 41.

That might be much tighter than you’ve ever had them before!

Tension the backstay to 15% of its breaking load.

Note: Using ordinary hand-tools on the bottlescrews, it’s hard to over-tension the rigging

Step 4: Tighten the lowers / babystay

A mast should bend forward in the middle, though only to a small extent on masthead rigs of heavy section.

This ‘pre-bend’ is principally to counter two factors in heavy weather: increased forestay loads pulling the top of the mast forward, and the head of a reefed mainsail pulling the middle aft.

Together, they can result in the middle of the mast bowing aft, which makes it unstable and is bad for sail trim. For maximum strength in extremis it should be straight.

Use the forward lowers or babystay to pull the middle of the mast forward. The bend thus induced should be no more than half the mast’s fore-and-aft measurement.

Then take up the slack in the aft lowers.

They don’t need to be tight; they’re just countering the forward pull.

Sight up the luff groove to make sure the mast is straight laterally. Correct any deflections with the lowers.

If you set up the caps properly to start with, you should not adjust them again at this stage.

Step 5: Check the rig under sail

First, make sure the leeward cap shroud isn’t waving around in the breeze. You should be able to deflect it with a finger by a few inches; no more.

If it’s too loose, take a turn or two on the leeward bottlescrew, then tack and do the same on the other side.

Now sight up the back of the mast.

It should be straight athwartships and bending slightly forward in the middle.

Athwartships deflection might make it look as though the top is falling away to one side (see diagram), but it won’t be if it was centred properly in Step 1. Straighten the middle by adjusting the lowers

If it’s straight or bending aft in the middle, try increasing the backstay tension (but not beyond 30% of its breaking strain) and, if necessary, tensioning the forward lowers/babystay and slackening the aft lowers.

Remove any lateral bends by adjusting the lowers.

Once you’re happy, lock off the bottlescrews to make sure they can’t come undone.

Inverted bend (mast bowing aft in the middle) is bad for sail trim and potentially dangerous for the rig.

Setting up a fractional rig with single, aft-swept spreaders

Widely used on smaller cruisers and cruiser/racers, this configuration needs a very different approach from an in-line masthead rig

This stage is the same as with a masthead rig (scroll up).

Step 2: Set the rake

This time, however, rake is set by the forestay and cap shrouds rather than the forestay and backstay.

With a swept-spreader fractional rig it’s the cap shrouds, not the backstay, that stop the mast moving forward. They provide both fore-and-aft and lateral support, so they’re doing two jobs.

The backstay’s principal role is to control the topmast and mast-bend. Because it’s above the point where the forestay joins the mast, it’s not pulling directly against the forestay and therefore has less effect on forestay tension. How much it pulls against the forestay depends on factors including the height of the topmast, the stiffness of the mast section and the tension of the lower shrouds (which determine the bend).

Step 3: Tighten the cap shrouds

Forestay tension is achieved primarily through the caps, and because they’re swept back at such a shallow angle they need to be seriously tight.

Their maximum tension is 25% of breaking load, but it’s best not to tension them all the way in one go because that would result in a very bent mast: tensioning the caps pushes the spreaders, and therefore the middle of the mast, forward.

Start by taking them to about 15% of breaking load, then tighten the lowers to pull the middle of the mast back so it’s straight.

This is how the swept-spreader fractional rig works: the caps and lowers are working against each other, caps pushing and lowers pulling, to stabilise the middle of the mast. Sight up the mast when it’s straight to check for lateral deflection, correcting it with the lowers.

With a flexible mast you might need to repeat the process, taking the caps to 20% before tensioning the lowers again.

Otherwise go straight to the next stage, which is to pull on the backstay.

Since the backstays on fractional rigs often have cascade purchases at the bottom you can’t measure the tension by stretch as you can with wire, so you have to do this by feel: pull it tight, but don’t go mad.

Tensioning the backstay bends the mast and therefore shortens the distance from the hounds (where the caps join) to the deck. This loosens the caps, so it’s easier to tension them back to the 20% mark.

When you let the backstay off, the caps will tension again and should be at about 25% of breaking load – but no more.

Step 4: Set the pre-bend

Take a few turns on the lowers to achieve the right amount of pre-bend. It should be more than with an in-line masthead rig, but a mast should never bend to more than 2% of the height of the foretriangle even with the backstay tensioned (that’s about 180mm in 9m, or 7in in 30ft).

Check to see how far the mast bends with a tight backstay. The optimum bend will often be determined by the cut of the mainsail, or recommended by the sailmaker or class association.